Built to Rest

General Electric's CEO brings halachic experts into his innovation lab — so you can bring his fridge into your Shabbos kitchen

Photos: Equisport Photos

When my plane touched down at the Louisville airport, it was the beginning of Kentucky Derby Week, when the attention of millions of Americans turns to that state and the storied horse race it has hosted at Churchill Downs for well over a century. Only I wasn’t there to see the horses run, nor for that matter, to drink bourbon, another of Kentucky’s major claims to fame.

Instead, I’d come to spend a day at the Louisville headquarters of an iconic American company, General Electric Appliances (GEA), touring its plants and visiting its executive offices together with two Orthodox Jewish pioneers: Rav Tzvi Ortner, a leading expert in issues at the intersection of halachah and technology and head of the Orthodox Union’s department devoted to that area, and Eli Antebi of the Clifton, New Jersey-based ZMAN Technologies. Working closely with Rav Ortner and ZMAN, GEA has embarked on an initiative unprecedented in corporate America, incorporating the halachic aspects of home appliances into the very fabric of its design and manufacturing processes. Dozens of its engineers have spent thousands of hours working to ensure that the entire GEA product line — from oven ranges to refrigerators and, perhaps soon, hot-water heaters — can be used in full, l’chatchilah compliance with halachah, no corners cut or leniencies taken.

GEA’s unusually strong working relationship with ZMAN Technologies, an Orthodox-run technology enterprise, led to the invention of the “Shabbos Keeper” technology that’s making it possible for busy balabustas to comfortably operate their kitchens throughout a three-day Yom Tov. And on an eye-opening visit to GEA’s sprawling 900-acre industrial complex called Appliance Park in Louisville — so large it has its own zip code — we saw it firsthand.

But the story of the two-way channel between GEA and Orthodox Jews is also an object lesson in the unlimited possibilities that are unleashed when a major American business — one with over 15,000 employees and manufacturing plants in five states — adopts a philosophy of “the customer is king” not merely as cliché, but as a day-to-day operating model. The appliance maker has been around for a very long time — its onetime parent company, General Electric, was founded in 1907 — and it has an equally long reputation for forward-looking innovation. Among its firsts were the self-cleaning oven and the over-the-range microwave, and it also pioneered the manufacture of both WiFi-connected appliances and those utilizing voice assistants.

Americans who grew up decades ago remember well the ubiquitous radio ads of corporate giant General Electric (GE), ending with the jingle “We bring good things to life.” When GE’s home appliances business was acquired in 2017 by the multinational Haier Corporation, it became known as General Electric Appliances (GEA) — and it tweaked the old tagline, too, changing it to “good things, for life.” For growing numbers of Orthodox Jewish consumers, those four words carry added meaning, because for them GEA has become synonymous with good things that enhance their lives every Shabbos and Yom Tov.

Today, GEA is one of the country’s leading appliance manufacturers, whose products can be found in more than half of all American homes, but when Kevin Nolan took the helm as CEO in 2017, he made it his goal for GEA products to become a fixture of every home across the country. Under his stewardship, the company has become what he calls “a 100-year-old start-up,” jettisoning the traditional hierarchical structure to become a dynamic incubator of creativity, fueled by employee-driven initiative. He also promoted a company-wide approach of “zero distance,” which means getting as close as possible to the users of the products, listening to how they describe their needs and wants and then getting busy making products to match them.

But what happens when there’s a community of consumers that’s growing in numbers and affluence, for which GEA appliances do not meet their needs due to the requirements of their religious observance? For decades, practically since the invention of the first domestic electric refrigerator in the early 1900s, its use on Shabbos and Yom Tov had raised complex halachic issues. Then, with the advent of next-generation refrigerators, the challenges to halachic observance multiplied, becoming ever more complicated and seemingly insurmountable. Addressing these hurdles presented a real-time test case for GEA’s zero distance philosophy.

It was at the FirstBuild innovation lab that Shabbos Keeper was first conceived and designed. True to his zero-distance mindset, Nolan realized there was a huge demographic that needed Shabbos-friendly appliances, and refrigerators were at the top of the list

Joining Forces

The Gemara says that the creation of a human being involves shloshah shutafim, three partners, and the Shabbos Keeper, too, had its genesis in a collaborative effort among three parties to bring good things to life: Kevin Nolan, a born-and-bred New Englander familiar with the Jewish community and its needs, Rav Tzvi Ortner, an expert in conforming technology to the requirements of halachah, and Eli Antebi, director of ZMAN Technologies, a company dedicated to innovating halachically-compliant tech devices.

It was a fortuitous encounter ten years ago between Kevin Nolan and appliance retailer Michael (Motty) Gross at an appliance industry trade show that planted the earliest seeds from which the Shabbos Keeper would eventually sprout. Gross, the proprietor of AJ Madison, a major Boro Park-based appliance business, got to speaking with Nolan, then GE’s CTO, about his frum customers’ need for Shabbos and Yom Tov-compatible appliances, and he mentioned the name of Rav Tzvi Ortner as someone Nolan ought to get to know. It would still be several years on before Kevin Nolan and Rav Ortner would actually begin working together in earnest, but the connection had been made and the two stayed in touch.

Rav Ortner, a native of Eretz Yisrael who now makes his home in Boro Park, where he is also the rav of a kehillah, exudes a real passion for upgrading communal halachah observance, and its roots run deep. His father was the rav of the city of Lod in central Eretz Yisrael, and his father-in-law was Rav Shlomo Gross, the Belzer dayan of Boro Park. He has authored seforim on halachah and responds regularly to halachic queries, and he has a particular gift for finding ingenious solutions to problems that arise at the interface of halachah and technology.

Recognizing Rav Ortner’s unusual combination of deep knowledge of halachah and sophisticated technological know-how, Rav Yisroel Belsky a”h, whose own expertise in scientific aspects of halachah was legend, enthusiastically encouraged him to focus on appliance usage on Shabbos and Yom Tov, an area of halachah he believed had been neglected for too long. And that’s how Rav Ortner teamed up with ZMAN Technologies, which specializes in the intersection between halachah and technology.

“When we first started,” Rav Ortner recalls, “there was a discussion about whether to first tackle the issues involving ovens or those of refrigerators. The reason we went with the latter is two-fold: First, the halachic challenges presented by ovens are greater, and people are used to making Shabbos without an oven by using crockpots, hot plates, and blechs. But a refrigerator is something no one wants to do without.”

Eventually, Rav Ortner approached Kevin Nolan about the possibility of creating a prototype of a device that could bypass all of a refrigerator’s automated features, and Nolan welcomed the idea warmly.

Up to the Challenge

Kevin Nolan’s lean, athletic build and youthful features belie his background as a seasoned engineer with over three decades of corporate experience under his belt. And although his ready smile is both genuine and disarming, underneath it is a real competitor who’s laser-focused on the brass ring. “We’re the fastest-growing appliance company in the US,” he observes, “and we play to win.”

A native of Stamford, Connecticut, Kevin earned a degree in a degree in mechanical engineering at the University of Connecticut, and in 1989 joined GE straight out of school. Eight years later, he moved to the company’s appliance division, where he eventually spent a decade as Chief Technology Officer (CTO). In 2017, he assumed the mantle of chief executive, but his tenure has shown him to be a very different kind of corporate leader. Perhaps we might call him the Un-CEO.

“Five years ago,” Mr. Nolan says, “when we joined the Haier organization, we were a good business with stagnant growth, slow decision making, and a risk-averse culture. I knew the potential, and with our new ownership, that potential has been unleashed. Over the last five years, we’ve embraced a transformative new mindset, promoting a winning mentality, pursuing zero distance with our owners, and empowering every employee to become an entrepreneur.”

Nolan is a self-described “creator and maker at heart” who personally holds 29 patent awards. Innovation, he says, is “what fuels me and gets me excited. I love the whole creative process of coming up with an idea and bringing it to market.”

In 2014, when Nolan was still the CTO at GE, it was that inventive spirit that led him to take the lead role in launching FirstBuild, which is essentially an innovation lab and micro-factory all-in-one. And it was there that the Shabbos Keeper was first conceived and designed, and where it continues to be manufactured.

Located in Kentucky on the campus of the University of Louisville, not far from Appliance Park, FirstBuild is a truly unique phenomenon in the vast landscape of American industry: a “maker space” dedicated to open-source innovation, where anyone — whether a seasoned inventor with multiple patents or a complete novice — can take a product idea from concept through design, engineering, manufacturing, and sales. FirstBuild is an independent entity, but it’s backed by the resources and know-how of GEA and staffed in part by engineering students from the university.

Nolan took the first step in developing an authentic Shabbos-friendly refrigerator by sending FirstBuild’s manager at the time, Larry Portaro, out to ZMAN’s headquarters in Clifton to launch the project. True to his zero-distance mindset, Nolan realized that the observant Jewish community is one large consumer demographic in need of home appliance solutions — how to use them in a halachically optimal manner every seventh day, plus on the many holidays spread throughout the year. This was a challenge tailor-made for FirstBuild to address.

“I think a lot of manufacturers have struggled with this,” Nolan observes, “because the Jewish community is hard to understand from the outside, since the lifestyle is so different. But I think growing up where I did helped me in that regard, because I had so many Jewish friends, and even though they weren’t Orthodox, being over on the holidays and such gave me some understanding of things. I went to Stamford High School, which was down the street and across the way from the big Orthodox Jewish school there.”

Nolan acknowledges that ZMAN’s successful partnership with GEA could well be replicated by others in the appliance industry, and he welcomes that. “If we can encourage other manufacturers to open up and start thinking differently about this, then we’ll get more and more innovation of this kind. And the new technologies allow for customizing appliances, so it’s getting easier and easier to do these things.” After all, he says, GEA went into its collaboration with the Orthodox community “based on having faith that if you serve a community right, good things happen. A typical company might want to know right away, ‘What’s the payback?’ But that’s not what this was about.”

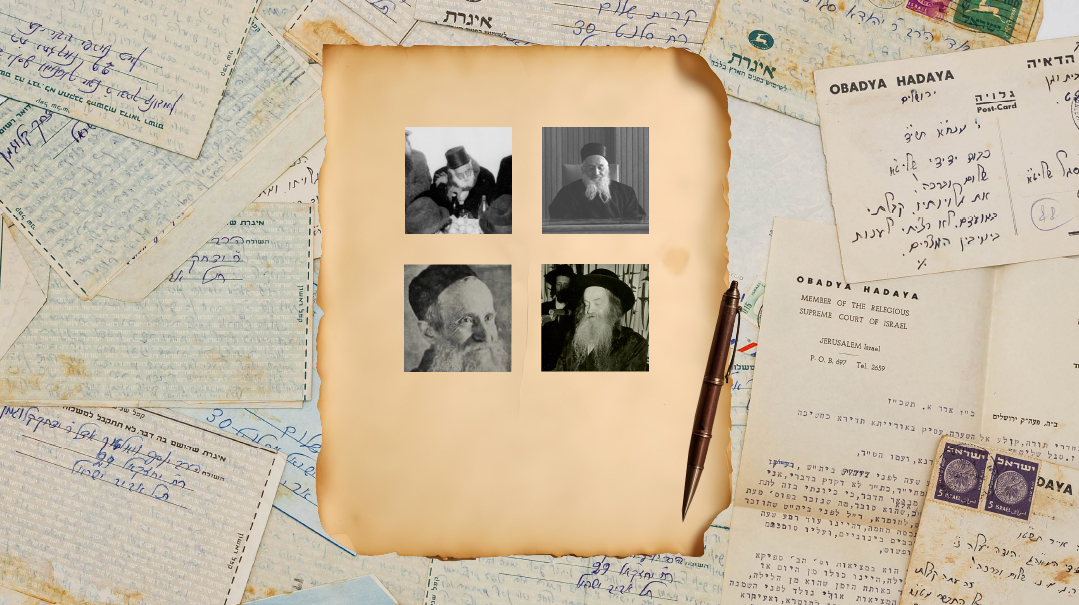

CEO Kevin Nolan (R) promoted a company-wide approach of getting as close as possible to the actual consumers, but would he be able to meet the needs of the Orthodox public? Team players Eli Antebi of ZMAN and Rav Tzvi Ortner, and Mishpacha’s Eytan Kobre see the results

Cold Comfort

The old-style refrigerators of decades past raised fewer halachic issues, albeit serious ones. Opening the door would mean activating a switch that turned on the fridge light, a mechanical thermostat that activated the compressor, and a timer triggering the heating element for defrosting the freezer. Many in the frum community came to rely on the lenient rulings of certain poskim, most prominently Rav Shlomo Zalman Auerbach, permitting the opening of refrigerator doors provided the light was turned off in advance.

Most of today’s high-tech models, however, incorporate features that make it almost impossible to use without risking possible transgression of various melachos such as havarah, kesivah, and makeh b’patish. These include electronic counters monitoring the number of times refrigerator doors are opened, frost sensors regulating refrigerator moisture levels, and compressors running continually but at variant power levels, and none of those can be circumvented the way switches could be. These new models all have various lights, touch screens, and internal computers, and added enhancements like water dispensers and ice makers, all of which would seem to render the refrigerator simply off-limits to Shabbos use.

Enter Shabbos Keeper, a device that in one fell swoop has revolutionized the halachah-compliant use of appliances on Shabbos and Yom Tov. In essence, it’s a mini-computer that easily attaches to a refrigerator and is programmed to activate the refrigerator’s Shabbos mode prior to the arrival of Shabbos. While in this mode, the interior lighting stays on at reduced brightness; door switches and sensors are automatically deactivated; the defrost is set to automatically activate every few hours; and the cooling features are time-controlled rather than based on usage patterns.

Prior iterations of a Shabbos mode-style solution required the user to remember to activate the mode each Erev Shabbos, and forgetting to do so meant spending Shabbos sans refrigeration. Since the Shabbos Keeper is preprogrammed with the weekly times of Shabbos arrival and departure through the year 2050, that’s no longer a concern. Each Friday afternoon, 90 minutes before sunset, it automatically sets the refrigerator to Enhanced Shabbos Mode, which overrides every sensor and computer signal, thereby removing virtually every impediment to Shabbos use without the need to rely on any halachic leniencies. It remains in that mode until 90 minutes following Shabbos, when it reverts back to regular weekday mode.

If there’s a power failure on Shabbos that shuts the refrigerator down for several hours, does that undo Shabbos mode and make the refrigerator unusable for the remainder of Shabbos? The company’s engineers thought of that, too, and saw to it that information is stored for up to 72 hours, enabling the proper mode to be activated when the power comes back on.

Once a Shabbos Keeper had been developed for the refrigerator, the team turned their attention to the more complex area of oven ranges.

The Shabbos mode for ovens, like the one for refrigerators, disables all lights, sensors, alerts, and buttons on the appliance, and also disables the standard automatic safety shutoff so the user doesn’t cause the over to go off during Shabbos. It also adjusts temperatures automatically during Shabbos, thereby allowing the oven door to be opened and closed as many times as needed throughout the entire Shabbos or Yom Tov period so that food can be removed incrementally on Friday night and Shabbos day.

On Yom Tov, four hours before each mealtime, the oven temperature automatically increases to 350°F to enable cooking and baking as necessary. After four hours, it drops back down to a warm setting for the rest of the day, so that the kitchen does not overheat and no energy is wasted.

On Erev Shabbos and Yom Tov, the Shabbos Keeper automatically switches the oven into Shabbos Mode and starts warming at 18 minutes before sunset, and once Shabbos or Yom Tov is over, the oven resumes normal operation. But what if the user won’t be home for Shabbos or Yom Tov and doesn’t want Shabbos Mode to activate? ZMAN’s solution was to create a prompt that goes off early on Erev Shabbos or Yom Tov, eight hours before candle-lighting time, and asks the user to accept Shabbos mode. Once the user does so, she can continue cooking normally until 18 minutes before shkiah, when the Shabbos or Yom Tov mode setting goes on automatically.

Rav Ortner shares news of his latest project, the creation of a wireless Shabbos Keeper with a seven-inch display screen that will communicate with all the different Shabbos-compatible appliances in the kitchen, a central device for making sure they’re all operating in proper Shabbos mode. “And we’re working with TAG,” he adds, “to make it a kosher wireless device that’s safe for a Jewish home, because it’s dedicated only for this purpose.”

Double Endorsement

Over time, the Shabbos Keeper project has come to involve the efforts of over forty engineers in several departments at GEA, who focus on each model of refrigerator and oven separately, working out all the kinks in order to ensure that it can be operated safely and efficiently while in Shabbos mode. Every time a new model comes onto the market or an existing model incorporates a new feature, these engineers must go back to the drawing board to certify that it is Shabbos mode-compatible.

The Shabbos Keeper has earned a coveted double endorsement, with both the chassidic rabbinical group Hisachdus Harabonim (also known as the CRC) and the OU endorsing it as successfully obviating all issues of Shabbos and Yom Tov use, to which Rav Ortner has added his personal certification.

On a recent visit to Louisville to meet with Kevin Nolan and the Shabbos Keeper engineering team, Rav Ortner and Eli Antebi brought out Rav Hillel Weinberger, a senior posek for the Hisachdus, to personally inspect GEA’s new model of a double oven in order to determine whether it could be used to bake milchigs and fleishigs simultaneously. Perhaps that was not the first time a chassidisher posek traveled to an inspection in Kentucky, but without doubt the scene was an unlikely one: Kevin Nolan, a Connecticut Yankee, striding down the wide corridors of GEA headquarters together with Rav Weinberger and Rav Ortner, both attired in full chassidish levush.

As I make my way around the maze of offices and plants in Appliance Park together with Rav Ortner and Eli, it’s clear from the greetings they receive and their easy interactions with everyone they encounter that although they’re not GEA employees, they are very much part of the team — which, after all, is exactly what “zero distance” is all about.

“The amazing thing,” Eli observes, “is that Kevin’s vision filtered down to everyone, and they share his passion for this. Kevin has brought us deep in, so when we go to the factory, they recognize us as ‘the Shabbos people.’ When we go to the innovation center, they know the ‘Shabbos people.’” Rav Ortner agrees: “It comes from the top. Everyone here knows this is Kevin’s baby.”

“Every Wednesday,” Nolan points out, “we put out an employee video, and we’ve had these gentlemen on that video, so everybody knows them,” although he admits that he has difficulty pronouncing the guttural “ch” in “Hisachdus Harabonim,” and had Eli Antebi had to coach him on that. Still, says Eli, “he cared enough to pronounce it in the right way, instead of taking the easy way out and just saying ‘CRC.’ ”

Within the company, people call Kevin Nolan’s trailblazing corporate approach the “GEA Way” — which, as it happens, is also the name of the road wending its way through the massive Appliance Park.

As Nolan puts it, “We all have only one boss, and that’s not me — it’s our owners.” In GEA-speak, “owner” is a term for “customer,” and that isn’t just high-minded talk with no practical relevance, either. In its shift from a company-centric to a customer-centric way of doing business, GEA has dispensed with the traditional corporate structure involving a top-down hierarchy of decision-making, instead placing a great degree of control over decisions in the hands of its employees, empowering them to create the kinds of products that consumers are actually looking for.

The result, he says, is a “multitude of exploding, independent microenterprises within the business. These microenterprises aren’t led by me — they’re led by our employees who are closest to the work, who guide their decision-making based upon the wants and needs of the market. I might carry the title of CEO, but the traditional corporate titles we still carry don’t really reflect the work we do. As a CEO, I’m not the decision-maker who centralizes all the processes and leads from the top of the org chart. I am one more entrepreneur among the many we have in the company. I look at my role as more of an organizational architect and business coach. Power resides in your ideas and the value you create to users and not the level you have in the Human Resources systems.”

All of this is very personal for Nolan. “The thing that used to make me crazy as an engineer is that we’d come up with these ideas that I knew really had potential, but they would get killed in red tape, and we’d miss the opportunity window. Maybe that’s why I am so passionate about this new GEA Way model. It’s freeing up our people to create and seize opportunities. It’s amazing what people can do when we as CEOs get out of the way and create space for people to do the jobs we hired them to do.”

Relinquishing top-down control over the creative process has paid big dividends for the company, which for the past five years has experienced double-digit earnings growth that’s greater than ever before. By focusing on what consumers want and turning decision-making over to employees, GEA has been able to shrink the time needed to take a new appliance from abstract idea to finished product from two years down to only three months. That, in turn, has meant more GEA product lines overall and more products brought to market.

Regarding his partnership with ZMAN, Kevin gives credit all around. “You can’t do something like this unless you’ve got the three parties involved: ZMAN, the OU/Hisachdus, and us. We each brought something unique to the table. And, of course, it’s been fun watching the engineers, because they’re fundamentally curious people and they love solving problems. So they look at this as ‘Here’s a problem, what can we do to solve it?’”

Into Hot Water

Having addressed the halachic issues of both refrigerators and ovens, ZMAN and GEA are now approaching an ambitious new frontier: the use of hot water in the kitchen on Shabbos.

Until recently, GEA only sold hot water heaters made by others, but it has now begun in-house production of its own very energy-efficient model, featuring a well-insulated water tank which retains heat and a mixing valve that mixes cold water with the hot before releasing it for use. When water in the tank reaches a temperature of 160°F, the hot water heater shuts off. As a result of the water cooling down and the mixing of cold water, water is released for use at a temperature of 120°F,

Although the hot water heater was designed this way to enable the use of less power and less hot water, ZMAN and GEA’s engineers are now exploring the possibility that these features will enable the GEA hot water heater to be adapted for Shabbos use.

Customer First

Kevin Nolan’s excitement is infectious as he describes the singular nature of his brainchild, FirstBuild, the innovation lab where Shabbos Keeper was first conceived and designed.

“It’s a world-class co-creation community that is changing the way products come to market,” he says. “By letting a community influence the product from the very beginning, we can quickly deliver better products to market, infusing zero distance into everything we do. And although most people say you’ve got to keep innovation secret, we said ‘No, we’re going to make it public, let everyone see it.’ ”

Anyone can come in off the street into the facility’s workspace and encounter an entire community of industrial designers, engineers, and amateur inventors all freely using FirstBuild’s heavy-duty tools and machines to design, build, and ultimately market their home appliance creations.

Typically, FirstBuild will make and sell up to a thousand units of a new product; once consumer demand exceeds that number, GEA may choose to include it in its product line and begin producing it at Appliance Park. Even then, the inventor will continue to receive a share of total sales revenues and can market the product to other companies, even to GEA’s competitors, with GEA still benefiting from having been first to market with the product.

At FirstBuild’s inception, Nolan gave its staff his three expectations: that it would launch a minimum of 12 products a year; that at least one of those would succeed enough to graduate to production by GEA; and that the enterprise would break even. The yearly 12-product quota motivates the First Build staff to always be on the lookout for different niche communities whom it can serve by developing products to suit their needs and wants.

Some of FirstBuild’s success stories are upscale extravagances, products like a pizza oven that replicates in the comfort of one’s own home kitchen the experience of wood-fired oven pizza-making, producing a pizzeria-quality pie in under two minutes. The price tag for this product, which graduated to become part of GEA’s luxury Monogram line of wall ovens, is hefty — a cool $12,000 — but many others are much more affordable. Examples include an indoor pellet smoker that makes possible kitchen countertop barbequing and a mushroom fruiting chamber with the humidity controls and lighting needed to grow exotic types of mushrooms.

Then there are the products that serve the real needs of specific user communities, enabling them to surmount the obstacles presented by various home appliances. An example is a voice activated washing machine which guides visually impaired individuals in being able to navigate the various wash settings. This project got its start when an inventor learned that the advent of touch screen technology, with the constant changing of the screens, had rendered the utility of Braille dots obsolete.

(Originally featured in Mishpacha, Issue 916)

Oops! We could not locate your form.